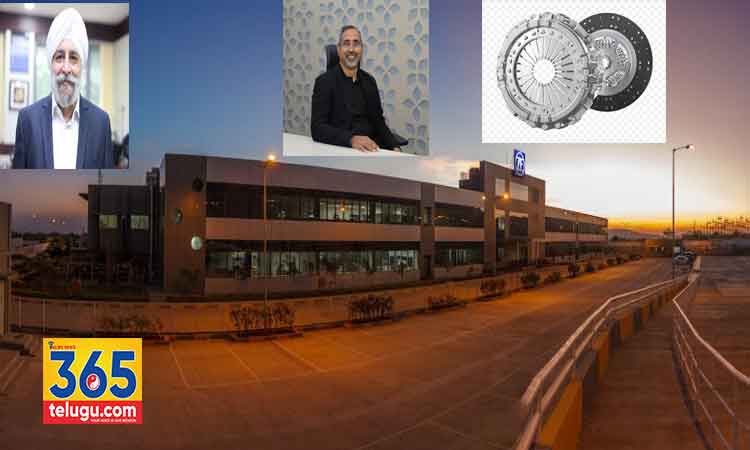

365telugu.com online news,India, October 8, 2025:ZF India Pvt Ltd. has clinched a significant contract to supply its locally engineered and manufactured 430mm heavy-duty clutch system to a leading Indian commercial vehicle manufacturer.

Tailored for high-performance engine platforms and optimized for India’s challenging operating conditions, this clutch solution underscores ZF’s expertise in delivering market-specific driveline technologies for both domestic and select export markets.

Signed in May 2025, the agreement entails supplying thousands of clutch units, with production commencing in mid-2026 at ZF’s Chakan facility in Pune. This deal reinforces ZF’s commitment to localization, strengthening its manufacturing presence in India and aligning with the ‘Make in India’ initiative.

Akash Passey, President – Region India, ZF Group, stated, “This business win reaffirms ZF’s focus on localization and innovation tailored for India. By combining our global technological expertise with robust local manufacturing, we deliver advanced, market-ready solutions that meet international standards. This partnership solidifies India’s position as a pivotal hub for ZF’s commercial vehicle business.”

Paramjit Singh Chadha, Sr. Vice President – CVS Division (India), ZF Group, added, “This contract highlights the strength of our heavy-duty clutch technology, designed to excel in India’s demanding conditions. The 430mm clutch system ensures durability, superior performance, and compatibility with future driveline architectures, including AMT. Local production at our Chakan plant supports our customers’ growth in domestic and export markets while advancing the ‘Make in India’ vision.”

The clutch system is engineered for robust performance, offering extended replacement intervals and lower total cost of ownership for fleet operators. It enhances ZF’s role in driving innovation within India’s commercial vehicle sector, reshaping the mobility landscape.

Key Features of the Clutch System

- Enhanced Durability: Advanced lining materials extend clutch life by up to 20%, minimizing maintenance costs and downtime.

- Improved Driver Comfort: Optimized clutch load ensures a smoother, less fatiguing driving experience while prolonging clutch longevity.

- Future-Proof Design: Compatible with both Manual Transmission (MT) and Automated Manual Transmission (AMT) systems.